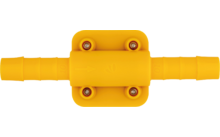

Valves & Shut-off Valves

Valves And Shut-Off Valves give you precise control over your caravan or motorhome water supply. Use mini ball valves, non-return valves and drain cocks to isolate branches, prevent backflow and winterise quickly. Choose food-grade, BSP-compatible parts for clean, leak-tight performance on every trip.

Read more about Valves & Shut-off Valves ...

Valves And Shut-Off Valves

Reliable valves are essential for a clean, quiet and serviceable water system. With the right shut-off valves, check valves and drain cocks, you can isolate branches, protect pumps and make maintenance faster at the pitch and on the road.

Caravan And Motorhome Valves Basics

Match valve type to its job: shut-off valves for isolation, non-return valves to stop backflow and drain valves for winterising. Keep diameters consistent across pipes and hoses to minimise pressure loss.

Choosing Sizes For Valves

Most fresh-water lines use 10–12 mm ID. Select smooth-bore valves sized to your layout so flow remains steady even at peak demand.

Materials And Food-Grade Compliance

Use food-grade plastics or approved metals for drinking water. Pick temperature-resistant options near heaters and in warm lockers.

Shut-Off Valves For Easy Servicing

Install mini ball valves before taps, heaters and filters so you can service one branch without draining the whole system. Label each line to speed up troubleshooting.

Outlet Isolation On Water Distributors

Fitting a small shut-off valve on each manifold outlet keeps kitchen, washroom and shower circuits independent and reduces downtime.

Leak Prevention With Shut-Off Valves

Before travel, close non-essential branches. After maintenance, pressure-test and recheck compression or push-fit joints.

Non-Return Valves For Backflow Protection

Place check valves after the pump or near elevated tanks to maintain pressure and prevent reverse flow. Choose low-opening-pressure designs for quiet operation.

Positioning Non-Return Valves

Install horizontally or vertically as specified by the manufacturer, and add a strainer upstream to protect the mechanism from debris.

Combining Check Valves And Filters

When space is tight, use compact inline filters with integrated non-return features to save joints and keep flow tidy.

Drain Valves And Winterising

Low-point drain valves allow fast emptying of hot and cold circuits to prevent frost damage. Add caps or plugs to keep dirt out during storage.

Quick Winterising Routine

Open all drains, set mixer taps mid position and run the pump briefly to purge lines. Leave valves open until dry, then close and cap inlets.

Frost Protection Tips

In colder regions, consider thermostatic frost valves that open automatically to protect vulnerable sections without supervision.

BSP Threads, Connectors And Sealing

Many taps, heaters and inlets use BSP threads. Confirm size and male/female orientation, then seal with the specified gasket or PTFE tape without overtightening.

Push-Fit And Compression Connections

Deburr pipe ends, mark insertion depth and push fully home on push-fit valves. For compression fittings, align carefully and tighten gradually to avoid crushing pipe.

Maintaining Your Valves On The Road

Carry spare O-rings, a couple of mini ball valves and a universal adapter. Cycle valves periodically to prevent sticking and inspect for micro-leaks after your first drive.